Consultants Providing Strategic Management Solutions

Our Mission

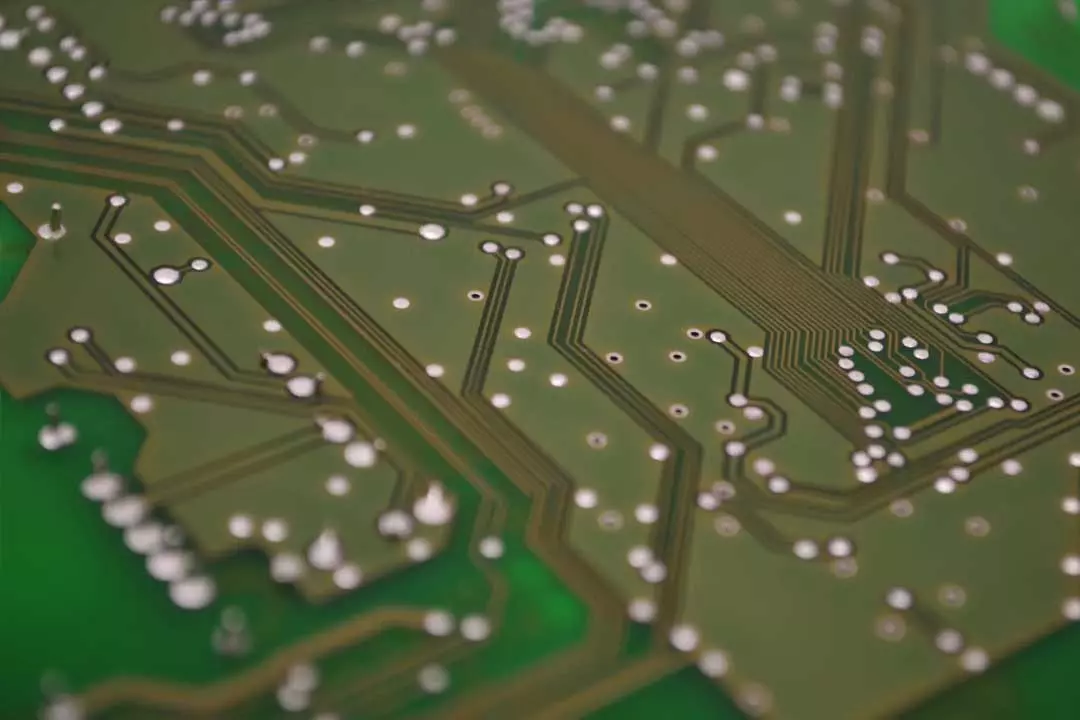

At ITM Consulting, we prepare our electronics assembly clients for tomorrow’s challenges by teaching and applying the principles that underlie the issues of today. We strive to earn your trust and respect by providing innovative, effective, and successful solutions to both technical and business challenges.

We are committed to providing prompt, responsive, and effective advisory services in the most cost-efficient manner possible. Our primary goal is to create a long-lasting collaboration and a mutually rewarding relationship with every client.

Our Mission

At ITM Consulting, we prepare our electronics assembly clients for tomorrow’s challenges by teaching and applying the principles that underlie the issues of today. We strive to earn your trust and respect by providing innovative, effective, and successful solutions to both technical and business challenges.

We are committed to providing prompt, responsive, and effective advisory services in the most cost-efficient manner possible. Our primary goal is to create a long-lasting collaboration and a mutually rewarding relationship with every client.

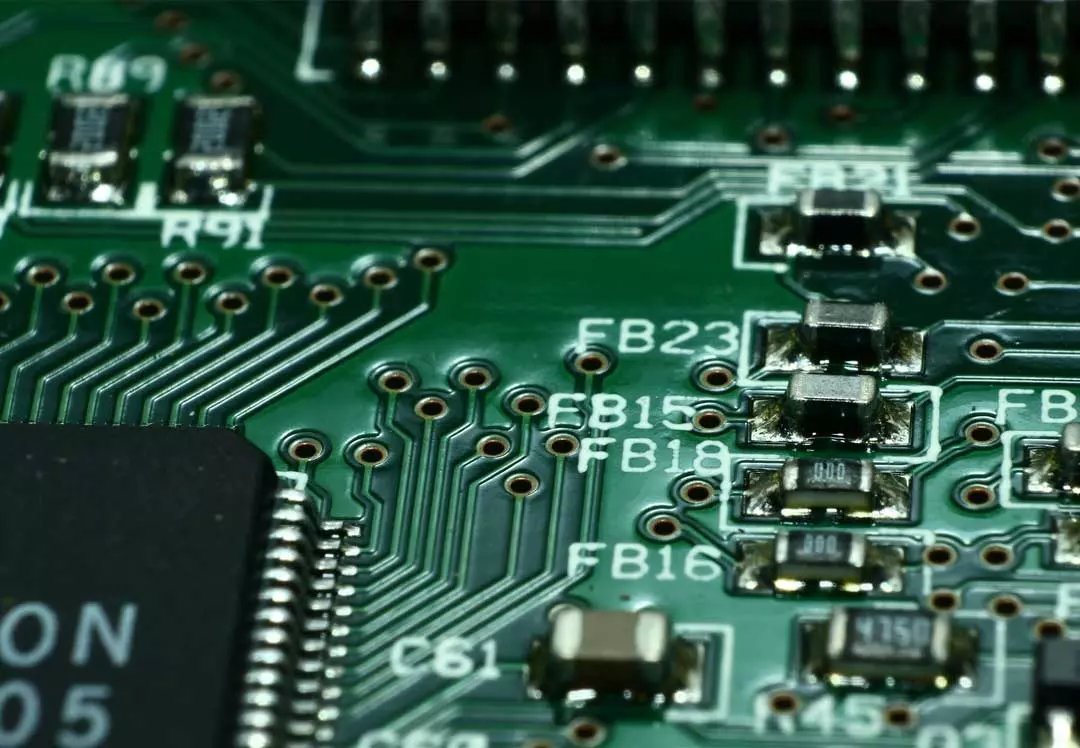

Experience and Expertise

The ITM Team's vast experience with equipment manufacturers facilitates techno-marketing work with many leading equipment manufacturers. One service, unique to electronics consulting, is equipment benchmarking. This service, often copied but never duplicated, thoroughly tests and evaluates equipment performance, the level of technology, and substantiates or refute claims made by the manufacturer. Regardless of the service provided, ITM Consulting practices the edict:

We don’t tell you what you want to hear — we tell you what you need to know.

With our Consultants' extensive manufacturing experience, much of our work for both OEMs and contract assemblers (CEMs) are projects that focus on assembly process troubleshooting as well as Risk Assessment. ITM Consulting is also well known for our thorough and comprehensive process audits wherein an electronic assembler’s entire process is reviewed and evaluated resulting in yield improvement recommendations..

ITM Consulting also works with OEMs in helping them evaluate and select the CEM that best fits their needs. Once again, our Consultants' experience working with a major CEMs and OEMs have given us insight into the intricate details that matter. Our experise has time and time again proved beneficial to clients who did not want to make mistakes in their outsourcing endeavors.

Turn to Us to Learn More About Case Studies

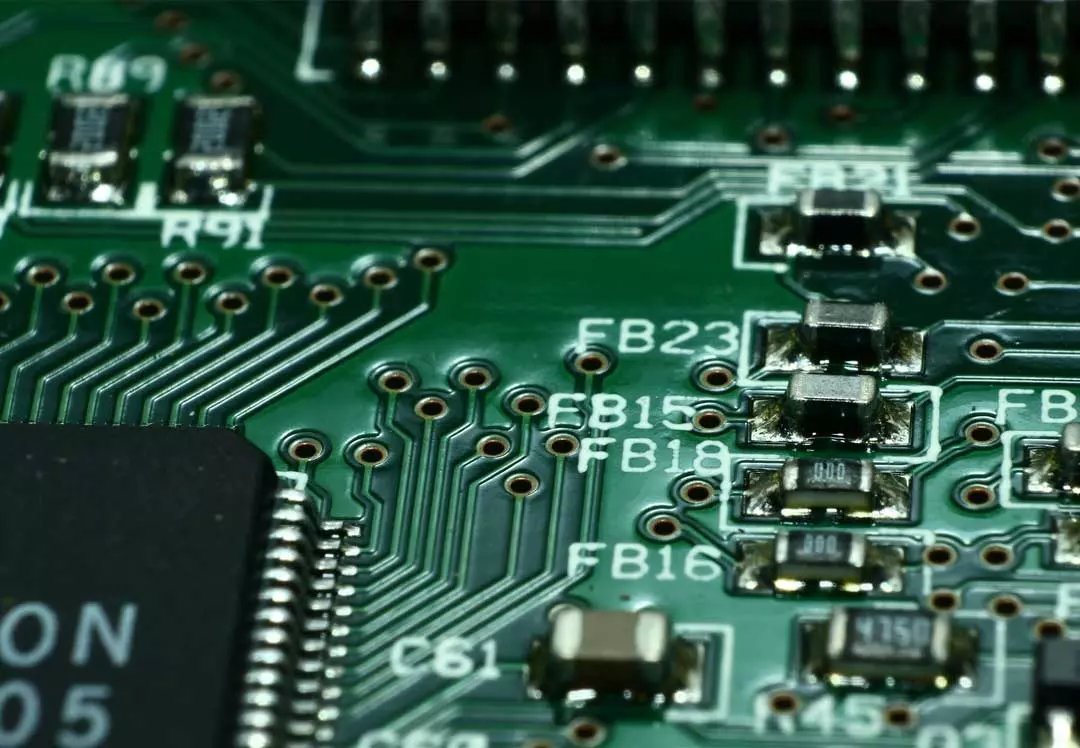

Case Studies

Military and Commercial Manufacturer of Microwave Devices - USA

- OEM Manufacture of highly complex PCBAs for use in AWACS satellite systems

- Low Volume / Low Mix

- Q/R Class 3; NASA and other specs

- End user wanted 3rd-party assessment and certification of Fabrication and Assembly Processes

- ITM audited both PCB fabrication and PCB assembly processes.

- Recommendations included areas of material handling, operating procedures, and other documentation, calibration control, and inspection criteria.

- Recommendations were implemented and client received both ITM Fabrication and Assembly Certification.

- Improved yields realized.

- The end user was satisfied with the improvements.

- Client has since been re-certified.

Fortune 100 Automotive Electronics Manufacturer - USA

- OEM Manufacture of automotive engine management control systems, auto entertainment systems.

- Very High Volume / Medium Mixv

- Q/R Class 2; Automotive

- Corporate wanted SMT and Through-hole assembly process and quality systems reviewed.

- Weak areas to be identified and assessed with goal to improve throughput and yields.

- ITM audited two facilities in the US (engine control module assembly) and two facilities in Mexico (automotive entertainment systems).

- Recommendations included areas of documentation not be adhered to and process control problems.

- Implementation of Lean Manufacturing had gone too far and was impacting quality.

- Recommendations generated improved product quality and higher first pass yield.

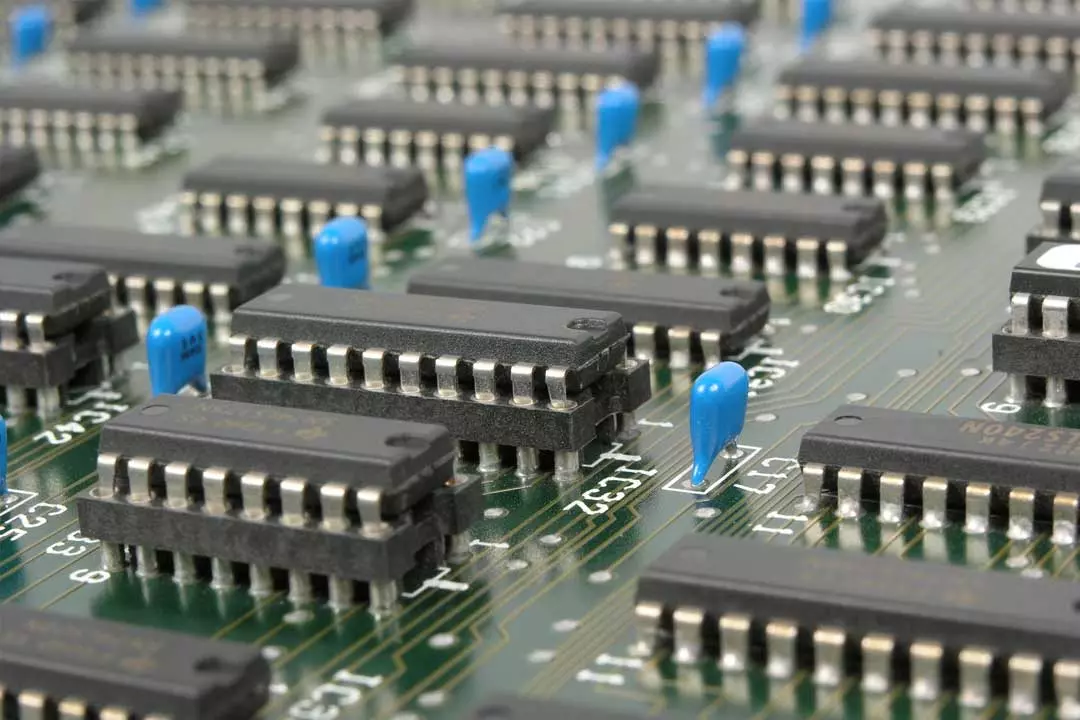

Fortune 50 Medical Equipment Manufacturer - USA and Italy

- OEM Manufacture of medical equipment.

- Low volume / Medium Mix

Q/R Class 3; FDA and other specs - Field failure of heart/blood perfusion system manufactured for client in Italy prompted investigation of supply chain.

- Possible root cause(s) of failure to be identified and assembly and quality systems rectified to assure highest quality and prevent future occurrences.

- ITM audited design and box-build/test facility, PCB fabricator, and PCB assembler (CEM), all located in Modena, Italy.

- Documentation was found to be weak in key areas.

- Root cause was determined to be in assembly due to lacking ESD procedures and best practices.

- While other improvements were also recommended in Test, Box-build/Final Assembly as well as DFM, another CEM was ultimately qualified based upon ITM guidelines.

Fortune 100 Manufacturer of Power Conversion Equipment - USA and Philippines

- OEM Manufacturer of Uninterruptable Power Supplies and Battery Backup Systems

- Assembling in the Philippines with a Korean CEM

- High Volume / Low Mix

- Q/R Class 2; Consumer and industrial applications

- Client was in the final stages of converting their assembly processes and materials to lead-free for the purpose of being in compliance with the EU RoHS directive.

- ITM performed a process audit / lead-free gap analysis to assure world-class practices in electronic assembly as well as identify possible weak points in assuring RoHS compliance.

- Recommendations included areas of quality systems, material control and documentation adherence as well as several process procedures.

- Follow-up audit saw improved quality yields and reliable RoHS compliance.

- ITM certified the Lead-free assembly process.

BOARD TALK

BOARD TALK